Amidst China's "dual carbon" strategic goals, power cables, crucial for urban electricity transmission and distribution, are transforming toward green, low-carbon solutions. However, the high energy consumption and non-recyclability of traditional cross-linked polyethylene (XLPE) cable insulation pose significant barriers to their sustainable development. Eco-friendly polypropylene (PP) cable insulation has emerged as a promising alternative due to its low energy consumption during production and recyclability during decommissioning.

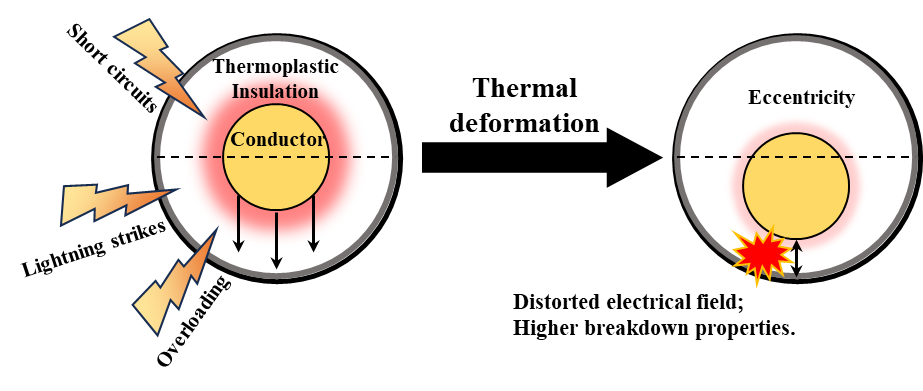

Nevertheless, the room-temperature modulus of PP insulation is significantly higher than that of XLPE insulation, hindering cable laying and installation. Although toughness improvement via elastomer modification, the temperature stability of the mechanical modulus of non-crosslinked PP insulation deteriorates markedly, resulting in thermal deformation of the PP cable insulation at elevated temperatures during actual operation, potentially leading to cable eccentricity faults. Hence, enhancing temperature stability is a pivotal challenge in the research of polypropylene cable insulation.

Schematic diagram of cable eccentricity fault caused by the stability of polypropylene insulation

To address this issue, a research group led by Professor Jianying Li from the School of Electrical Engineering, Xi'an Jiaotong University, the State Key Laboratory of Electrical Insulation and Power Equipment, in collaboration with the Institute of Chemistry, Chinese Academy of Science; China Electric Power Research Institute; Yanshan Petrochemical; and Jiangsu Shangshang Cable Group, has introduced multiple long-chain branching (LCB) structures into the multiphase structure of isotactic polypropylene (IPC) insulation, achieving a remarkable improvement in the temperature stability of eco-friendly polypropylene cable insulation.

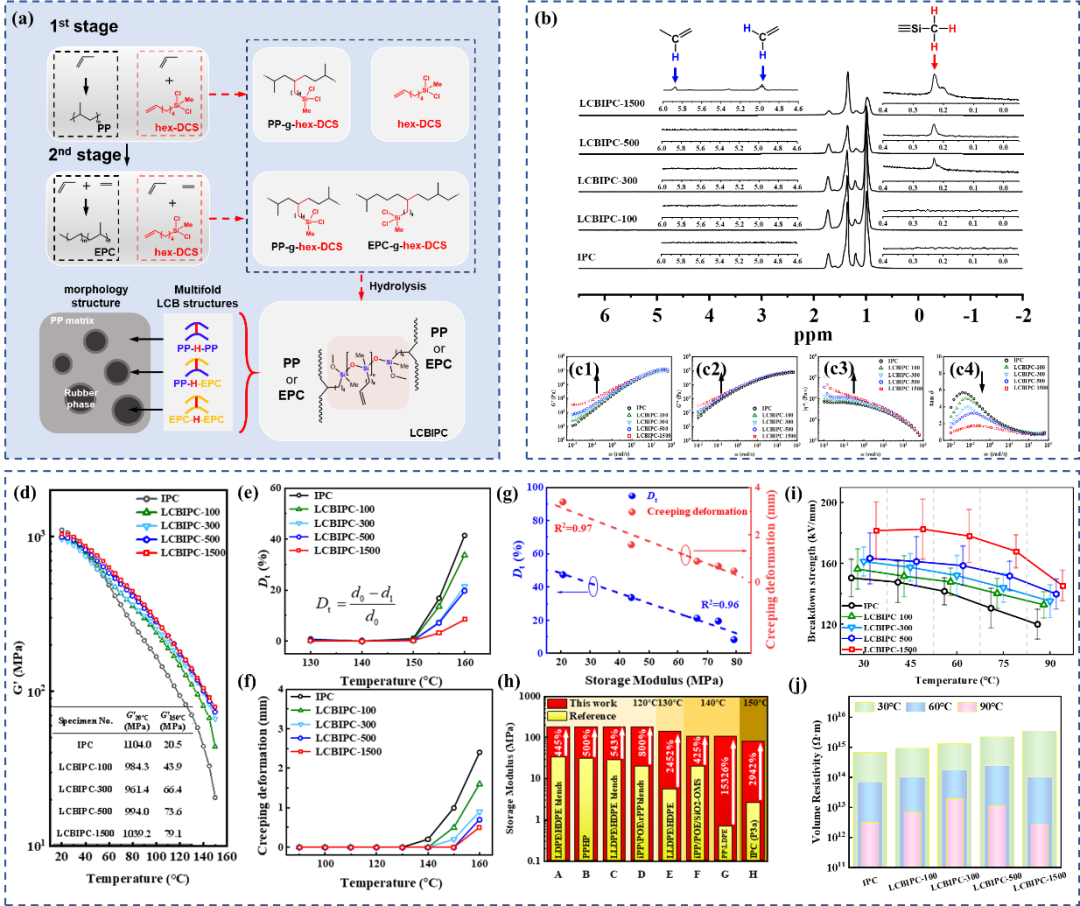

The results indicate that compared to IPC, LCBIPC exhibits a 13% reduction in modulus at room temperature (20℃) and a nearly 300% increase at 150℃. Under extremely high of 160℃, the creep strain and thermal deformation of LCBIPC are reduced by 85% and 82%, respectively.

The study suggests that LCBIPC can inhibit the thermal expansion of the amorphous region by enhancing the entanglement effect of molecular segments, while significantly improving temperature stability and various electrical properties in a wide temperature range from 30℃ to 90℃. Additionally, the study confirms that LCBIPC retains good recyclability, with no significant change in melt index after multiple reshaping processes.

This research has overcome the bottleneck of limited temperature stability of eco-friendly polypropylene cable insulation, providing essential theoretical and technical support for improving the operational reliability of polypropylene cables.

Design, characterization, and significantly enhanced temperature stability of multifold long-chain branched structure: Long-chain branched isotactic polypropylene (a) synthetic route and its (b) nuclear magnetic resonance (NMR) spectrum, (c) shear rheological characterization results; (d) temperature dependence of mechanical modulus; (e) thermal deformation rate and (f) thermal creep at different temperatures; (g) high-temperature mechanical modulus dependence of thermal deformation rate and thermal creep; (h) high-temperature mechanical modulus of long-chain branched isotactic polypropylene compared with literature results; temperature dependence of (i) AC breakdown strength and (j) volume resistivity of long-chain branched isotactic polypropylene

The research team has developed in-situ polymerized polypropylene insulation materials and semiconductor shielding materials, achieving a continuous and stable production capacity of 200,000 tons per year and a stable integrated long-cycle preparation level. They have also developed manufacturing equipment and technology for medium-voltage polypropylene insulated power cables, overcoming the challenge of uniform shaping of polypropylene insulation, and realizing the design and stable manufacturing of shielded medium-voltage cables. The team proposed material performance evaluation indices for cable materials and reliability testing methods for power cables, establishing a standardization system from polypropylene cable materials to cables. Calculations show that the manufacturing cost of the new power cables is 17% lower than that of traditional power cables, and their production energy consumption is reduced by 45%.

Under the coordination of the Equipment Department of the State Grid Corporation of China, the China Electric Power Research Institute has taken the lead in formulating standardized polypropylene insulated power cable designs, technical specifications, and entry-to-network testing requirements, supporting the batch promotion and stable operation of power cable projects at 35kV and below. In May 2023, the technical of the team's project, "Key Technologies of In-Situ Polymerization of Polypropylene Insulation Materials and Manufacturing of Power Cables," passed the evaluation of the China Electric Power Enterprise Federation.

The aforementioned research findings were published in "Chemical Engineering Journal" under the title "Greatly Enhanced Temperature Stability of Eco-friendly Polypropylene for Cable Insulation by Multifold Long-chain Branched Structures." The study was supported by the National Natural Science Foundation of China's Key Projects and Youth Projects, the Open Research Project of the State Key Laboratory of Electrical Insulation and Power Equipment, and the Sinopec Science and Technology Project.